In recent years, with the rapid development of the automobile industry, the problems of fuel consumption, environmental protection and safety caused by automobiles have attracted more and more attention. Looking forward to the future development direction of the automobile industry, lightweight, low fuel consumption and low emissions are the development theme. According to the statistics of international authoritative departments, 60% of automobile fuel combustion energy is consumed by its own quality. Although high strength steel sheet, aluminum, magnesium, metal matrix composites and plastic resin materials have played a role in reducing the weight of automobiles, the emergence of industrial titanium materials has made automobile manufacturing possible. Better choices.

Titanium metal has the advantages of low density, high specific strength and good corrosion resistance. The use of titanium material in automobiles can greatly reduce the body quality, reduce fuel consumption, improve engine efficiency, improve the environment and reduce noise. But because of the high price, titanium alloys can only be used in luxury cars and sports cars, but seldom in ordinary cars. Therefore, the research and development of low-cost titanium alloys to meet the needs of the market is the key to promote its application in ordinary household cars.

Application Status of Titanium Alloy in Automotive Industry

Although titanium alloys have been widely used in aerospace, petrochemical and naval industries, their application in automotive industry has developed slowly. Since the first all-titanium automobile was developed by General Motors in 1956, titanium automobile parts did not reach the level of mass production until the 1980s. In the 1990s, with the increasing demand for luxury cars, sports cars and racing cars, titanium parts developed rapidly. In 1990, the amount of titanium used for automobiles in the world was only 50 tons, reached 500 tons in 1997, reached 1100 tons in 2002, and reached 3000 tons in 2009. It is expected that the amount of titanium used for automobiles in the world will exceed 5000 tons in 2015. Titanium alloy parts are commonly used as follows.

- Engine connecting rod

Titanium alloy is an ideal material for connecting rod. The engine connecting rod made of titanium alloy can effectively reduce engine mass, improve fuel utilization and reduce exhaust. Compared with steel connecting rod, titanium connecting rod can reduce the mass by 15%-20%. The application of titanium alloy connecting rod was first demonstrated in the new Italian Ferrari 3.5LV8 and Acura NSX engines. Ti-6Al-4V, Ti-10V-2Fe-3Al, Ti-3Al-2.0V and Ti-4Al-4Mo-Sn-0.5Si are the main materials used in titanium alloy connecting rods. Other titanium alloy materials such as Ti-4Al-2Si-4Mn and Ti-7M-4Mo are also being developed.

- Engine valves

The automobile engine valve made of titanium alloy can not only reduce the mass and prolong the service life, but also reduce the fuel consumption and improve the reliability of the automobile. Compared with steel valves, titanium valves can reduce mass by 30%-40% and increase engine speed by 20%. As far as current applications are concerned, Ti-6Al-4V is the main material of intake valve, Ti-6242S is the main material of exhaust valve, Sn and Al are usually added together to obtain lower brittleness and higher strength; Mo addition can improve the heat treatment performance of titanium alloy, strengthen the strength of quenching and aging titanium alloy, and increase the hardness. Other potential titanium alloys are:

1) Ti-62S can be used in the intake valve. Its characteristics are equivalent to Ti-6Al-4V, and the price is cheaper.

2) The exhaust valve can be Ti-6Al-2Sn-4.0Zr-0.4-Mo-0.45Si. Because of the low Mo content, the latent resistance of the exhaust valve is better than that of Ti-6242S, and the oxidation resistance temperature can reach 600 C.

3) The exhaust valve can be made of gamma-TiAl, which has the characteristics of high temperature resistance and light weight, but it is not suitable for traditional forging method, only suitable for casting method and powder metallurgy method.

- Valve spring seat

High strength and fatigue resistance are the necessary properties of valve spring seat. Beta titanium alloy is heat treatment alloy, which can obtain high strength through solution aging treatment. The suitable materials are Ti-15V-3Cr-3Al-3Sn and Ti-15Mo-3Al-2.7Nb-0.2Si. Mitsubishi automobile uses Ti-22V-4Al titanium alloy valve spring seat on its large-scale production vehicle, which reduces the mass by 42% compared with the original steel lock, reduces the inertia mass by 6%, and increases the maximum engine speed by 300 r/min.

- Titanium alloy spring

Titanium and its alloys have lower modulus of elasticity and larger_s/E value than steel, so they are suitable for manufacturing elastic components. Compared with steel automobile spring, titanium spring is only 40% of the height of steel spring and 30%-40% of the mass of steel spring on the premise of the same elastic work, which is convenient for car body design. In addition, the excellent fatigue and corrosion resistance of titanium alloy can improve the service life of spring. At present, Ti-4.5Fe6.8Mo-1.5Al and Ti-13V11C-3Al can be used to manufacture automotive springs.

- Turbocharger

Turbocharger can improve the combustion efficiency of the engine and increase the power and torque of the engine. Turbocharger rotor needs to work in high temperature exhaust gas above 850 C for a long time, so it requires good heat resistance. Traditional light metals such as aluminium alloys can not be used because of their low melting point. Although ceramic materials have been used in turbine rotors because of their light weight and good heat resistance, their application is limited because of their high cost and shape. In order to solve these problems, Tetsui et al. developed TiAl turbine rotor, which not only has good durability and performance, but also can improve the acceleration of the engine. This design has been successfully commercialized on the Mitsubishi Lancer Evolution series.

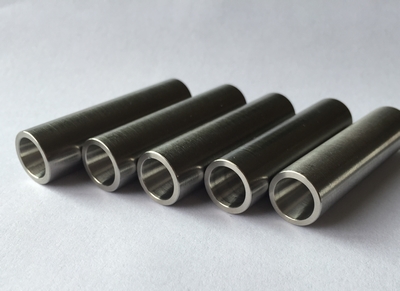

- Exhaust system and muffler

Titanium is widely used in automobile exhaust system. The exhaust system made of titanium and its alloys can not only improve reliability, life and appearance, but also reduce quality and improve fuel combustion efficiency. Compared with steel exhaust system, titanium exhaust system can reduce the mass by about 40%. In Golf series automobiles, the quality of titanium exhaust system can be reduced by 7-9 kg. At present, the main titanium used in exhaust system is industrial pure titanium.

Titanium muffler has a mass of only 5-6 kg, which is lighter than stainless steel muffler. In 2000 Chevrolet Corvette Z06 cars, an 11.8 kg titanium muffler and tail gas system replaced the original 20 kg stainless steel system, resulting in a 41% reduction in mass. The strength of the replaced system remains unchanged, making the car faster, more flexible and fuel-saving. Titanium used in mufflers is also mainly industrial pure titanium.

- Car body frame

In order to improve the safety and reliability of automobiles, it is necessary to consider design and manufacturing, especially manufacturing materials. Titanium is a good material used to make car body frame. It has not only high specific strength, but also good toughness. In Japan, automobile manufacturers choose pure titanium metal welding control as body frame, which can make drivers have enough sense of safety when driving.

- Other Titanium Alloy Components

In addition to the above components, titanium is also used in engine rocker arm, suspension spring, engine piston pin, automotive fasteners, hanging ear nuts, automotive door inrush beam, automotive baffle brake caliper piston, pin bolt, pressure plate, transmission button and automotive clutch round plate and other automotive parts.

Application of Titanium Alloys

- Advantages

Titanium alloys are widely used in automotive industry because of their light weight, high specific strength and good corrosion resistance. The most widely used titanium alloys are automotive engine systems. There are many advantages in using titanium alloy to manufacture engine parts, mainly in the following aspects:

1) The low density of titanium alloy can reduce the inertia quality of moving parts. At the same time, the titanium valve spring can increase the free vibration, reduce the body vibration, and increase the engine speed and output power.

2) Reduce the inertia quality of moving parts, so as to reduce friction and improve the fuel efficiency of the engine.

3) Selection of titanium alloy can reduce the load stress of related parts and reduce the size of parts, thus reducing the quality of engine and vehicle.

4) The reduction of inertia quality of components reduces vibration and noise and improves engine performance.

The application of titanium alloy in other parts can improve the comfort of personnel and the beauty of automobile. Titanium alloys play an immeasurable role in energy saving and consumption reduction in automotive industry.

- Application limitations

Although titanium alloy parts have such excellent properties, there is still a long way to go before titanium and its alloys are widely used in automotive industry. The reasons include high price, poor formability and poor welding performance.

With the development of near net forming technology of titanium alloy and modern welding technology such as electron beam welding, plasma arc welding and laser welding in recent years, the forming and welding problem of titanium alloy is no longer the key factor restricting the application of titanium alloy. The main reason that hinders the widespread application of titanium alloy in automobile industry is the high cost.

The price of titanium alloys is much higher than that of other metals in both initial smelting and subsequent processing. The cost of titanium parts acceptable to the automotive industry is $8-13 per kg for connecting rods, $13-20 per kg for valves, and less than $8 per kg for springs, engine exhaust systems and fasteners. At present, the cost of parts manufactured with titanium materials is much higher than these prices. The cost of production of titanium sheets is mostly higher than $33/kg, 6-15 times as much as that of aluminium sheets and 45-83 times as much as that of steel sheets.

Research status of titanium alloys for automobiles

At present, cost reduction is the main research direction of titanium alloys for automotive industry. In view of the characteristics of cost distribution of titanium alloys for automotive industry, materials researchers mainly aim at reducing costs from the following two aspects: developing new low-cost alloy systems and using new processing and preparation technologies.

- New Low Cost Titanium Alloy System

Researchers in various countries have developed new low-cost titanium alloy systems, focusing mainly on the following aspects: alloy design using cheap alloy elements and alloy design improving processing characteristics. Among them, Japan and the United States are the representatives. Two Low-cost Titanium alloys, Ti8LC and Ti12LC, have been successfully developed in China. In the composition design of Low-cost Titanium Alloys for automobiles, the commonly used low-cost alloying elements are Fe, Cr, Si, Al and so on.

- New Processing Technology

The processing cost of titanium alloys accounts for more than 60% of the total cost in the production process. Therefore, how to reduce the processing cost of titanium alloys has become the focus of research. The research in this field is mainly divided into two aspects: one is to improve the traditional casting and forging process, and the other is to adopt near net forming technology of powder metallurgy.

In the research and development of new forging technology, cold forging is one of the most promising methods for manufacturing automotive parts with titanium alloy. Beta titanium alloys have low deformation resistance at room temperature and good cutting and forming. They can be used for cold forging. At present, three kinds of cold deformation beta titanium alloys have been developed in Japan. Beta titanium alloy also has some shortcomings. It is easy to produce uneven deformation during cold forging, and it is easy to adhere to the die. Therefore, the mass production of beta titanium alloy parts by cold forging technology needs further exploration and development.

Powder metallurgy is an important technology in reducing the processing cost of titanium alloys. In the manufacturing of powder metallurgy automotive parts, the traditional pressing-sintering method is still in the leading position, mainly including element powder method (BE) and pre-alloyed powder method (PA). At present, elemental powder method is widely used in the field of low-cost automotive titanium alloy powder metallurgy because of its simple process and lower cost. In recent years, other powder metallurgy technologies, including laser forming technology and metal powder injection molding (MIM) technology, have been widely used in the trial production and production of complex automotive parts, which can greatly shorten the product development and production cycle and further reduce the cost.

epilogue

The new generation of automobile design pays more attention to lightweight body, low fuel consumption, low noise and light vibration of engine to meet the increasingly stringent requirements of the environment. In this context, light metal titanium will become a major choice for future automotive applications.

Considering the current research status of Low-cost Titanium Alloys for automobiles, we can find that in order to further reduce the cost of titanium alloys for automobiles, we should focus on the following aspects:

1) In the development of low-cost alloy systems, we should try our best to develop alloys that do not use or use less expensive alloy elements without affecting their properties. At the same time, we should fully develop and utilize recovered titanium alloys.

2) In the aspect of casting and forging process development, we should develop beta titanium alloy and cold-deformed titanium alloy, and study the feasibility of mass production.

3) In powder metallurgy, the performance of titanium parts should be further improved while ensuring the advantages of low cost.

With the development of economy and the reduction of titanium cost, more and more engineers will choose titanium parts as automobile parts. Titanium alloys will eventually play an important role in the automotive industry.