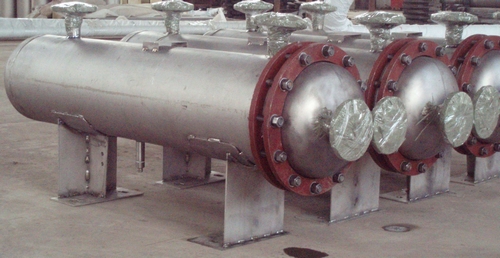

Titanium materials have the characteristics of high hardness, light weight and anti-corrosion. Because of the superior properties and characteristics of titanium materials, they are made into titanium equipment and widely used in industry, chemical industry and many other fields.

(1) Titanium has stronger corrosion resistance than stainless steel and aluminium in many media. Moreover, titanium has light weight and high specific strength.

Titanium passivation film is easily produced on its surface in air, oxidizing and neutral aqueous media, which makes the electrode potential of titanium shift positively and greatly improves the thermodynamic stability. The degree of chemical stability improvement after passivation is expressed by passivity coefficient. Iron is 0.18, nickel is 0.37, molybdenum is 0.49, chromium is 0.74, aluminium is 0.82, and titanium is 2.44.

(2) Titanium does not have the low temperature brittleness problem like ferrite steel. Titanium can be used as cryogenic vessels with temperatures as low as – 269 degrees, but because austenitic stainless steel, aluminum, copper, etc. can also be used as cryogenic vessels and are cheaper than titanium, titanium is seldom used as cryogenic fixed vessels in fact. Titanium is used as mobile cryogenic capacities in aviation and aerospace. Importantly, the device utilizes the characteristics of high specific strength, weight and light weight of titanium.

(3) In chlorine-containing media such as seawater and brine, corrosion resistance of carbon steel, low alloy steel, stainless steel and aluminium is not good, while titanium has unique excellent corrosion resistance. About 50% of titanium containers are used to resist corrosion of chlorine-containing media.

(4) Because the corrosion resistance of titanium is caused by the oxide film on the surface, the general industrial pure titanium and titanium alloys are not resistant to corrosion in high temperature hydrochloric acid and other strong reducing media. Ti-32Mo can resist hydrochloric acid corrosion, but its plasticity and technological properties are poor. Ti-32Mo has not been included in the standard of pressure-processed titanium material, nor is it included in this standard as titanium for container.

(5) Under certain conditions, fuming nitric acid, dry chlorine, methanol, trichloroethylene, liquid nitrogen tetroxide, molten metal salts, carbon tetrachloride and other media of titanium may produce combustion, explosion or stress corrosion, which may lead to malignant accidents of titanium containers. Titanium containers should avoid or carefully use these media.

(6) Titanium will burn in pure oxygen with temperature over 500 degrees or in air with temperature over 1200 degrees. Therefore, titanium containers should not touch open fire in case of contact with air and oxygen in order to avoid burning of titanium containers.

(7) The impact toughness of titanium materials and containers is generally not required to be tested.

(8) Titanium has excellent corrosion resistance. More than 90% of industrial pure titanium TA1, TA2 and TA2 are used in civil industry to make various kinds of titanium equipment, and 3/4 of these titanium equipment are used to make titanium containers. Therefore, titanium containers play an important role in the titanium industry in China.