- Overview

The nominal composition of TC11 titanium alloy is Ti-6.5Al-3.5Mo-1.5Zr-0.3Si. It is a kind of heat-resistant titanium alloy of alpha-beta type. Its aluminium equivalent is 3.5 and molybdenum equivalent is 7.3. The alloy also has good hot working properties (including conventional process properties and superplasticity), and can be welded and machined in various ways. The beta heat treatment and isothermal forging of the alloy have developed rapidly.

TC11 titanium rod

The alloy is also sensitive to hot salt stress corrosion.

The alloy is mainly used to manufacture compressor disc, blade, drum and other parts of aeroengine, and also can be used to manufacture aircraft structural parts. The maximum long-term working temperature of the alloy is 500 C by hot deformation and heat treatment in the alpha-beta region. The semi-finished products are bars, forgings and die forgings.

TC11 titanium alloy is a high temperature titanium alloy which is widely used in our country. The highest temperature is 500 C. It is mainly used in aeroengine compressor components, such as blades, discs, drums and shafts. It can also be used to make special-shaped castings. The working conditions of the castings are as follows: in annealing state, it can be used for 500 hours below 500 and 100 hours below 550 and under 450 for 1000 hours; in strengthening treatment state, it can be used for parts below 500 and parts under 700 for one-time work.

The similar brand is BT9 (Russia).

- Chemical Constituents

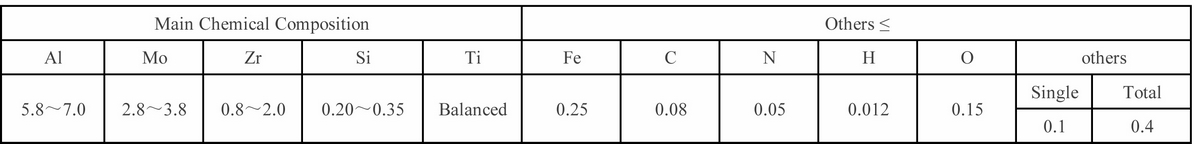

The chemical composition stipulated in GB/T 3620.1-2007 Titanium and Titanium Alloy Brands and Chemical Compositions is shown in Table 7-4-14.

Table 7-4-14 Chemical Composition /% of TC11 Titanium Alloy

- Overview

The nominal composition of TC11 titanium alloy is Ti-6.5Al-3.5Mo-1.5Zr-0.3Si. It is a kind of heat-resistant titanium alloy of alpha-beta type. Its aluminium equivalent is 3.5 and molybdenum equivalent is 7.3. The alloy also has good hot working properties (including conventional process properties and superplasticity), and can be welded and machined in various ways. The beta heat treatment and isothermal forging of the alloy have developed rapidly.

TC11 titanium rod

The alloy is also sensitive to hot salt stress corrosion.

The alloy is mainly used to manufacture compressor disc, blade, drum and other parts of aeroengine, and also can be used to manufacture aircraft structural parts. The maximum long-term working temperature of the alloy is 500 C by hot deformation and heat treatment in the alpha-beta region. The semi-finished products are bars, forgings and die forgings.

TC11 titanium alloy is a high temperature titanium alloy which is widely used in our country. The highest temperature is 500 C. It is mainly used in aeroengine compressor components, such as blades, discs, drums and shafts. It can also be used to make special-shaped castings. The working conditions of the castings are as follows: in annealing state, it can be used for 500 hours below 500 and 100 hours below 550 and under 450 for 1000 hours; in strengthening treatment state, it can be used for parts below 500 and parts under 700 for one-time work.

The similar brand is BT9 (Russia).

- Chemical Constituents

The chemical composition stipulated in GB/T 3620.1-2007 Titanium and Titanium Alloy Brands and Chemical Compositions is shown in Table 7-4-14.

Table 7-4-14 Chemical Composition /% of TC11 Titanium Alloy

III. ALLOY PROPERTIES

Density 4.48g/cm 3, room temperature modulus of elasticity 123 GPa, Poisson’s ratio 0.33, phase transition point 1000+20 C, hardness HB331-343 C.

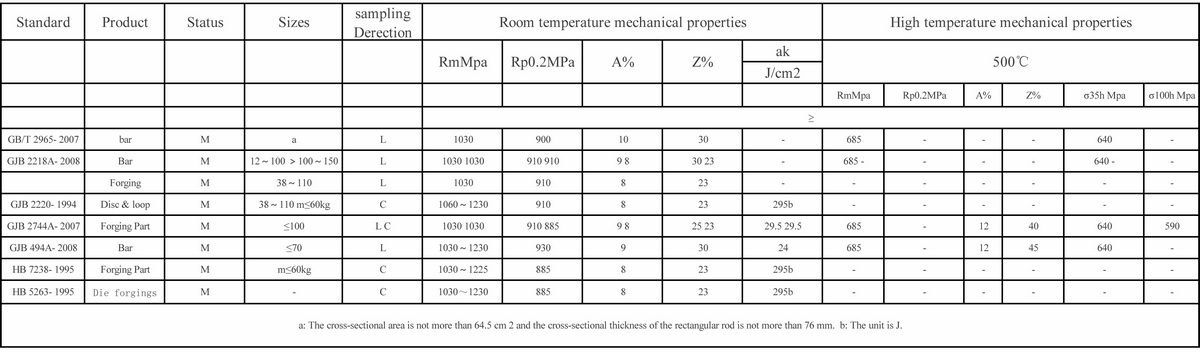

The performance specified in the technical standard is shown in Table 7-4-15.

Table 7-4-15 Performance of TC11 Titanium Alloy as specified in Technical Standards