Titanium alloy has been widely used in aviation, weapon equipment, naval ships and some light artillery because of its high strength, non-magnetic, good medium temperature, good weldability and corrosion resistance. In recent years, great progress has been made in the application of titanium alloy technology in China. At the same time, there are still some problems to be further studied. It is hoped that there will be greater breakthroughs in the field of processing technology in the future.

Titanium alloys have the characteristics of high temperature resistance, good weldability, high specific strength, easy processing and forming, and have been widely used in aerospace and aerospace fields. In addition, because of its unparalleled corrosion resistance of other materials, it has also been widely used in the ocean and industrial atmosphere. However, titanium alloy has some shortcomings, such as poor formability in cutting, which restricts its application to a certain extent.

CHARACTERISTICS OF TITANIUM ALLOY MATERIALS

Titanium alloys are not only steel in strength, but also light in weight, good corrosion resistance and good thermal stability. In addition to being widely used in aerospace and aerospace fields, titanium alloys are also widely used in biopharmaceutical and petrochemical industries. Titanium alloys have different properties and uses because of their different composition and structure.

(1) Characteristics of Titanium Alloys

Some alloying elements are added to titanium. According to the characteristics of the formed titanium alloys, titanium alloys are usually divided into the following categories:

(1) Alpha phase titanium alloy. This kind of titanium alloy is an alloy with close-packed hexagonal lattice structure. It has strong toughness and strength, and has strong oxidation resistance at high temperature. Its disadvantage is that its formability is poor and it can only be used in high temperature environment.

(2) Titanium alloy with beta phase. This kind of titanium alloy is a body-centered cubic structure alloy with good formability, but it is easy to be damaged in the case of contamination, so its application is not much. It needs to reach a certain aging before its strength can be improved.

(3) Alpha+beta phase alloys. This kind of titanium alloy has good room temperature strength and is easy to form, but its thermal strength is not ideal. After heat treatment and strengthening, it is suitable for parts with high strength requirements. It is not only used in large quantities, but also widely used.

Titanium alloys have good properties at both high and low temperatures, so they can be used in a wide range of applications. It has low density and high strength, so its specific strength is higher. At the same time, titanium alloys have good corrosion resistance in sea water, atmosphere or acidity and alkalinity conditions, which makes titanium alloys become the best choice of corrosion resistant materials in many metal materials. However, its thermal conductivity will be low, and it is generally applicable to all kinds of insulation components.

Titanium alloys also have some disadvantages. That is to say, it lacks good wear resistance, so it is impossible to make some moving parts. The modulus of elasticity is relatively low and lower than that of magnesium and aluminium. Its processing and manufacturing process is more complex, and its production cost will be higher.

- Cutting of Titanium Alloys

Titanium alloys contain a variety of alloying elements, including some high activation energy elements, which are relatively stable in the alloy, so titanium alloys have great energy in plastic deformation, but also have a certain degree of workability. However, the thermal conductivity of titanium alloys is poor. In cutting process, the cutting heat gathers on the tool, unlike in aluminum cutting process, the cutting heat is taken away by chips. As a result, the thermal load of titanium alloy material is large and the cutting tool is damaged. Therefore, the common method to improve production efficiency by increasing the amount of removal per unit time is not suitable for the processing of titanium alloy materials. Therefore, suitable processing methods should be selected for different titanium alloy materials.

(1) Titanium alloys have high strength, toughness and hardness, so the hardening problem in cutting is serious, which needs to be treated with annealing. Especially when there are scratches or notches on the workpiece surface, because they are very sensitive to deformation speed, they are prone to scratches or cracks in the cutting process, so the processing speed must be controlled in order to proceed at a low speed.

(2) In general, titanium alloys have good thermal stability and high temperature resistance. Compared with aluminium alloys, the strength of titanium alloys is much higher. In cutting process, the thermal conductivity of titanium alloy is very low, which is equivalent to a small part of iron and aluminium materials. Its heat is concentrated on the cutting edge. When the temperature exceeds a certain standard, it will produce high chemical activity and react with oxygen and hydrogen in the air, thus reducing its plasticity, and worsening tool wear when it contacts with the cutter face and chips.

(3) In cutting, because there is a certain friction between titanium alloy and cutting tool, with the increase of friction speed, the temperature will be higher, the power will be higher, the tool wear will be faster, and it is easy to bond, thus greatly shortening the service life of the cutting tool. Therefore, the rational selection of cutting tools is also very important. Usually, some cemented carbide materials such as tungsten cobalt cemented carbide tools are selected. This can effectively prevent the generation of bad stress in the process of processing and ensure the processing accuracy of components.

These characteristics of titanium alloy in the cutting process make it very difficult to cut, resulting in lower production efficiency and higher production cost. Therefore, in order to improve the processing quality of titanium alloy, it is necessary to constantly improve the processing plan and adjust the reasonable processing parameters in the cutting process of titanium alloy.

- Welding Processing of Titanium Alloys

In recent years, in addition to some traditional titanium alloy processing technology, there are also some new processing methods, such as low temperature cutting, laser, ultrasonic and electromagnetic cutting. Especially with the development of welding technology, the processing and application of titanium alloys are more extensive. Because of the physical and chemical characteristics of titanium alloy, the weld is easily oxidized and nitrided, which results in pollution, and the joint is sensitive to embrittlement. Therefore, it is a great challenge to weld titanium alloy.

(1) Tungsten Argon Arc Welding

Tungsten Argon Arc Welding is the most common method in Titanium Alloy welding. Under the protection of argon, tungsten pole acts as the electrode and the weld metal is well protected. However, this welding method has low welding production efficiency, large post-weld structural deformation, coarse grain size of welded joint and poor protection, which will seriously affect the welding process. Weld quality. It is only suitable for thin plate welding or bottom welding.

(2) Laser welding is a high energy density welding method. Using this method to weld titanium alloy can not only reduce the defects of traditional processing technology, but also effectively refine the microstructures and grains of the weld and improve the performance of the weld. However, the power of this welding method is small, the laser beam absorbed by the welded workpiece surface is very low, and there are some threshold problems. It is only suitable for special materials or special requirements for processing structure, and is limited to the processing of small and precise parts, so it is more difficult than traditional processing technology.

(3) Friction stir welding (FSW) is a better technology among many new plastic joining processes. When friction stir welding is used, because of the low heating temperature, the defects in the weld zone are the least, and the structure and properties of the joints are good, so the effective welding of titanium alloys can be realized. However, this method has high requirements on the mixer head and its material, and has no good adaptability, and the process is not mature, so it can only be used in the welding of simple components.

(4) Electron beam welding (EBW) is characterized by high welding energy, strong penetration, large depth-width ratio of welds, isolation of atmospheric pollution and good performance of welded joints, which can realize the welding of titanium alloy thick plates. However, this method requires to be carried out in vacuum, limited by the size and shape of the parts processed, can not be produced in batches, and the requirements for equipment are also very high, the production cost is high, which limits its application scope.

(5) Laser-arc hybrid welding is a good welding technology for titanium alloys. It combines the advantages of laser welding and arc welding, with concentrated energy density, stable arc and good weld performance. However, its welding process parameters are too many to be controlled effectively, and its operation process is too complex, so it is only in the research stage at present.

For the welding process of titanium alloy, no matter which new technology or new method, there are some advantages and disadvantages to some extent. With the extensive application of titanium alloy materials in many fields, new welding processes and methods need to be continuously studied to improve the quality of welds and welding production efficiency, to ensure the welding quality of titanium alloy structural parts and meet the requirements of use.

Nowadays, titanium alloys have been widely used for their unique excellent properties, so the processing technology of titanium alloys has become a hot research topic. Compared with some advanced countries, China still has a certain gap in titanium alloy materials and processing technology. With the rapid development of modern technology, the application field of titanium alloy is also expanding year by year. This requires us to strengthen the optimization and innovation of processing technology, and constantly accumulate technical experience. It is of great significance for our country to make full use of titanium alloy materials by high quality products to meet the application requirements in various fields.

The compressive strength of titanium and its alloys is not lower than their tensile strength. The compressive yield strength and tensile yield strength of industrial pure titanium are approximately equal, while the compressive strength of Ti-6Al-4V and Ti-5Al-2.5Sn alloys is slightly higher than the tensile strength. The shear strength is generally 60%-70% of the tensile strength. The compressive yield strength of titanium and titanium alloy sheets is 1.2-2.0 times of the tensile strength. In normal atmosphere, the rupture strength of processed and annealed titanium and titanium alloys is (0.5-0.65) times the tensile strength. The durable strength of annealed Ti-6Al-4V was 0.2 times of tensile strength when 107 fatigue tests were carried out in notch state (Kt=3.9). The hardness of the highest purity processed industrial pure titanium is usually less than 120HB, while the hardness of other purity processed titanium is 200-295HB. The hardness of pure titanium castings is 200-220 HB. The hardness of titanium alloy under annealing is 32-38HRC, which is equivalent to 298-349HB. The hardness of as-cast Ti-5Al-2.5Sn and Ti-6Al-4V alloys is 320HB, and that of low gap impurity Ti-6Al-4V castings is 310HB. Tensile elastic modulus of industrial pure titanium is 105-109 GPa, and that of most titanium alloys is 110-120 GPa under return condition. Age hardening titanium alloy has a slightly higher tensile modulus than annealed titanium alloy, and the compressive modulus is equal to or greater than the tensile modulus. Although the stiffness of titanium and titanium alloys is much higher than that of aluminium and aluminium alloys, it is only 55% of that of iron. The specific modulus of elasticity of titanium alloys is the same as that of aluminium alloys, which is second only to beryllium, molybdenum and some superalloys. The torsional or shear modulus of industrial pure titanium is 46 GPa, and the shear modulus of titanium alloy is 43-51 GPa. In order to improve the strength of titanium alloy and increase the content of interstitial elements, the impact resistance and fracture toughness of the alloy will be harmful. According to the different types and states of titanium alloys, the impact strength of Charles notch of industrial pure titanium is 15-54J/cm2, and the casting state is 4-10J/cm2. The impact strength of titanium alloy under annealing is 13-25.8J/cm2, and the aging state is slightly lower. The impact strength of Cast Ti-5Al-2.5Sn alloy with V-notch is 10J/cm2, and that of Ti-6Al-4V alloy is 20-23J/cm2. The lower the oxygen content is, the higher the value is. Many titanium alloys have high fracture toughness, or good crack propagation resistance. The annealed Ti-6Al-4V alloy is a kind of material with excellent toughness. When notch concentration factor Kt = 25.4mm, the ratio of notch tensile strength to non-notch tensile strength is greater than 1. Titanium alloys can also maintain certain properties at high temperatures. General industrial titanium alloys can maintain their useful properties at 540 C, but they can only be used for a short time. The temperature range for a long time is 450 – 480 C. Titanium alloys for use at 600 C have been developed. Titanium alloys can be used as missile materials for a long time at 540 C and for a short time at 760 C. Titanium and titanium alloys can maintain their original mechanical properties at low and ultra-low temperatures. With the decrease of temperature, the strength and ductility of titanium and titanium alloys increase gradually. Many annealed titanium alloys have sufficient ductility and fracture toughness at – 195.5 C. Ti-5Al-2.5Sn alloy with very few interstitial elements can be used at – 252.7 C. The ratio of notched tensile strength to non-notched tensile strength is 0.95-1.15 at – 25.7 C. Liquid oxygen, liquid hydrogen and liquid fluorine are important propellants for missiles and cosmic devices. The low temperature properties of materials used to make cryogenic gas containers and cryogenic structures are very important. The ductility of titanium alloy is still above 5% when the microstructure is equiaxed and the content of interstitial elements (oxygen, nitrogen, hydrogen, etc.) is very low. Most titanium alloys have poor ductility at – 252.7 C, while the elongation of Ti-6Al-4V alloys can reach 12%.

The compressive strength of titanium and its alloys is not lower than their tensile strength. The compressive yield strength and tensile yield strength of industrial pure titanium are approximately equal, while the compressive strength of Ti-6Al-4V and Ti-5Al-2.5Sn alloys is slightly higher than the tensile strength. The shear strength is generally 60%-70% of the tensile strength. The compressive yield strength of titanium and titanium alloy sheets is 1.2-2.0 times of the tensile strength. In normal atmosphere, the rupture strength of processed and annealed titanium and titanium alloys is (0.5-0.65) times the tensile strength. The durable strength of annealed Ti-6Al-4V was 0.2 times of tensile strength when 107 fatigue tests were carried out in notch state (Kt=3.9). The hardness of the highest purity processed industrial pure titanium is usually less than 120HB, while the hardness of other purity processed titanium is 200-295HB. The hardness of pure titanium castings is 200-220 HB. The hardness of titanium alloy under annealing is 32-38HRC, which is equivalent to 298-349HB. The hardness of as-cast Ti-5Al-2.5Sn and Ti-6Al-4V alloys is 320HB, and that of low gap impurity Ti-6Al-4V castings is 310HB. Tensile elastic modulus of industrial pure titanium is 105-109 GPa, and that of most titanium alloys is 110-120 GPa under return condition. Age hardening titanium alloy has a slightly higher tensile modulus than annealed titanium alloy, and the compressive modulus is equal to or greater than the tensile modulus. Although the stiffness of titanium and titanium alloys is much higher than that of aluminium and aluminium alloys, it is only 55% of that of iron. The specific modulus of elasticity of titanium alloys is the same as that of aluminium alloys, which is second only to beryllium, molybdenum and some superalloys. The torsional or shear modulus of industrial pure titanium is 46 GPa, and the shear modulus of titanium alloy is 43-51 GPa. In order to improve the strength of titanium alloy and increase the content of interstitial elements, the impact resistance and fracture toughness of the alloy will be harmful. According to the different types and states of titanium alloys, the impact strength of Charles notch of industrial pure titanium is 15-54J/cm2, and the casting state is 4-10J/cm2. The impact strength of titanium alloy under annealing is 13-25.8J/cm2, and the aging state is slightly lower. The impact strength of Cast Ti-5Al-2.5Sn alloy with V-notch is 10J/cm2, and that of Ti-6Al-4V alloy is 20-23J/cm2. The lower the oxygen content is, the higher the value is. Many titanium alloys have high fracture toughness, or good crack propagation resistance. The annealed Ti-6Al-4V alloy is a kind of material with excellent toughness. When notch concentration factor Kt = 25.4mm, the ratio of notch tensile strength to non-notch tensile strength is greater than 1. Titanium alloys can also maintain certain properties at high temperatures. General industrial titanium alloys can maintain their useful properties at 540 C, but they can only be used for a short time. The temperature range for a long time is 450 – 480 C. Titanium alloys for use at 600 C have been developed. Titanium alloys can be used as missile materials for a long time at 540 C and for a short time at 760 C. Titanium and titanium alloys can maintain their original mechanical properties at low and ultra-low temperatures. With the decrease of temperature, the strength and ductility of titanium and titanium alloys increase gradually. Many annealed titanium alloys have sufficient ductility and fracture toughness at – 195.5 C. Ti-5Al-2.5Sn alloy with very few interstitial elements can be used at – 252.7 C. The ratio of notched tensile strength to non-notched tensile strength is 0.95-1.15 at – 25.7 C. Liquid oxygen, liquid hydrogen and liquid fluorine are important propellants for missiles and cosmic devices. The low temperature properties of materials used to make cryogenic gas containers and cryogenic structures are very important. The ductility of titanium alloy is still above 5% when the microstructure is equiaxed and the content of interstitial elements (oxygen, nitrogen, hydrogen, etc.) is very low. Most titanium alloys have poor ductility at – 252.7 C, while the elongation of Ti-6Al-4V alloys can reach 12%. The compressive strength of titanium and its alloys is not lower than their tensile strength. The compressive yield strength and tensile yield strength of industrial pure titanium are approximately equal, while the compressive strength of Ti-6Al-4V and Ti-5Al-2.5Sn alloys is slightly higher than the tensile strength. The shear strength is generally 60%-70% of the tensile strength. The compressive yield strength of titanium and titanium alloy sheets is 1.2-2.0 times of the tensile strength. In normal atmosphere, the rupture strength of processed and annealed titanium and titanium alloys is (0.5-0.65) times the tensile strength. The durable strength of annealed Ti-6Al-4V was 0.2 times of tensile strength when 107 fatigue tests were carried out in notch state (Kt=3.9). The hardness of the highest purity processed industrial pure titanium is usually less than 120HB, while the hardness of other purity processed titanium is 200-295HB. The hardness of pure titanium castings is 200-220 HB. The hardness of titanium alloy under annealing is 32-38HRC, which is equivalent to 298-349HB. The hardness of as-cast Ti-5Al-2.5Sn and Ti-6Al-4V alloys is 320HB, and that of low gap impurity Ti-6Al-4V castings is 310HB. Tensile elastic modulus of industrial pure titanium is 105-109 GPa, and that of most titanium alloys is 110-120 GPa under return condition. Age hardening titanium alloy has a slightly higher tensile modulus than annealed titanium alloy, and the compressive modulus is equal to or greater than the tensile modulus. Although the stiffness of titanium and titanium alloys is much higher than that of aluminium and aluminium alloys, it is only 55% of that of iron. The specific modulus of elasticity of titanium alloys is the same as that of aluminium alloys, which is second only to beryllium, molybdenum and some superalloys. The torsional or shear modulus of industrial pure titanium is 46 GPa, and the shear modulus of titanium alloy is 43-51 GPa. In order to improve the strength of titanium alloy and increase the content of interstitial elements, the impact resistance and fracture toughness of the alloy will be harmful. According to the different types and states of titanium alloys, the impact strength of Charles notch of industrial pure titanium is 15-54J/cm2, and the casting state is 4-10J/cm2. The impact strength of titanium alloy under annealing is 13-25.8J/cm2, and the aging state is slightly lower. The impact strength of Cast Ti-5Al-2.5Sn alloy with V-notch is 10J/cm2, and that of Ti-6Al-4V alloy is 20-23J/cm2. The lower the oxygen content is, the higher the value is. Many titanium alloys have high fracture toughness, or good crack propagation resistance. The annealed Ti-6Al-4V alloy is a kind of material with excellent toughness. When notch concentration factor Kt = 25.4mm, the ratio of notch tensile strength to non-notch tensile strength is greater than 1. Titanium alloys can also maintain certain properties at high temperatures. General industrial titanium alloys can maintain their useful properties at 540 C, but they can only be used for a short time. The temperature range for a long time is 450 – 480 C. Titanium alloys for use at 600 C have been developed. Titanium alloys can be used as missile materials for a long time at 540 C and for a short time at 760 C. Titanium and titanium alloys can maintain their original mechanical properties at low and ultra-low temperatures. With the decrease of temperature, the strength and ductility of titanium and titanium alloys increase gradually. Many annealed titanium alloys have sufficient ductility and fracture toughness at – 195.5 C. Ti-5Al-2.5Sn alloy with very few interstitial elements can be used at – 252.7 C. The ratio of notched tensile strength to non-notched tensile strength is 0.95-1.15 at – 25.7 C. Liquid oxygen, liquid hydrogen and liquid fluorine are important propellants for missiles and cosmic devices. The low temperature properties of materials used to make cryogenic gas containers and cryogenic structures are very important. The ductility of titanium alloy is still above 5% when the microstructure is equiaxed and the content of interstitial elements (oxygen, nitrogen, hydrogen, etc.) is very low. Most titanium alloys have poor ductility at – 252.7 C, while the elongation of Ti-6Al-4V alloys can reach 12%.

The compressive strength of titanium and its alloys is not lower than their tensile strength. The compressive yield strength and tensile yield strength of industrial pure titanium are approximately equal, while the compressive strength of Ti-6Al-4V and Ti-5Al-2.5Sn alloys is slightly higher than the tensile strength. The shear strength is generally 60%-70% of the tensile strength. The compressive yield strength of titanium and titanium alloy sheets is 1.2-2.0 times of the tensile strength. In normal atmosphere, the rupture strength of processed and annealed titanium and titanium alloys is (0.5-0.65) times the tensile strength. The durable strength of annealed Ti-6Al-4V was 0.2 times of tensile strength when 107 fatigue tests were carried out in notch state (Kt=3.9). The hardness of the highest purity processed industrial pure titanium is usually less than 120HB, while the hardness of other purity processed titanium is 200-295HB. The hardness of pure titanium castings is 200-220 HB. The hardness of titanium alloy under annealing is 32-38HRC, which is equivalent to 298-349HB. The hardness of as-cast Ti-5Al-2.5Sn and Ti-6Al-4V alloys is 320HB, and that of low gap impurity Ti-6Al-4V castings is 310HB. Tensile elastic modulus of industrial pure titanium is 105-109 GPa, and that of most titanium alloys is 110-120 GPa under return condition. Age hardening titanium alloy has a slightly higher tensile modulus than annealed titanium alloy, and the compressive modulus is equal to or greater than the tensile modulus. Although the stiffness of titanium and titanium alloys is much higher than that of aluminium and aluminium alloys, it is only 55% of that of iron. The specific modulus of elasticity of titanium alloys is the same as that of aluminium alloys, which is second only to beryllium, molybdenum and some superalloys. The torsional or shear modulus of industrial pure titanium is 46 GPa, and the shear modulus of titanium alloy is 43-51 GPa. In order to improve the strength of titanium alloy and increase the content of interstitial elements, the impact resistance and fracture toughness of the alloy will be harmful. According to the different types and states of titanium alloys, the impact strength of Charles notch of industrial pure titanium is 15-54J/cm2, and the casting state is 4-10J/cm2. The impact strength of titanium alloy under annealing is 13-25.8J/cm2, and the aging state is slightly lower. The impact strength of Cast Ti-5Al-2.5Sn alloy with V-notch is 10J/cm2, and that of Ti-6Al-4V alloy is 20-23J/cm2. The lower the oxygen content is, the higher the value is. Many titanium alloys have high fracture toughness, or good crack propagation resistance. The annealed Ti-6Al-4V alloy is a kind of material with excellent toughness. When notch concentration factor Kt = 25.4mm, the ratio of notch tensile strength to non-notch tensile strength is greater than 1. Titanium alloys can also maintain certain properties at high temperatures. General industrial titanium alloys can maintain their useful properties at 540 C, but they can only be used for a short time. The temperature range for a long time is 450 – 480 C. Titanium alloys for use at 600 C have been developed. Titanium alloys can be used as missile materials for a long time at 540 C and for a short time at 760 C. Titanium and titanium alloys can maintain their original mechanical properties at low and ultra-low temperatures. With the decrease of temperature, the strength and ductility of titanium and titanium alloys increase gradually. Many annealed titanium alloys have sufficient ductility and fracture toughness at – 195.5 C. Ti-5Al-2.5Sn alloy with very few interstitial elements can be used at – 252.7 C. The ratio of notched tensile strength to non-notched tensile strength is 0.95-1.15 at – 25.7 C. Liquid oxygen, liquid hydrogen and liquid fluorine are important propellants for missiles and cosmic devices. The low temperature properties of materials used to make cryogenic gas containers and cryogenic structures are very important. The ductility of titanium alloy is still above 5% when the microstructure is equiaxed and the content of interstitial elements (oxygen, nitrogen, hydrogen, etc.) is very low. Most titanium alloys have poor ductility at – 252.7 C, while the elongation of Ti-6Al-4V alloys can reach 12%.

Titanium pot is a pot made of 99.5% titanium metal as contact layer, pure aluminum as intermediate layer, magnetic conductive 430 stainless steel as bottom layer, three-layer composite structure, and integrated pressing. Why not use pure titanium single layer structure to make pots? That’s because both thermal conductivity (good thermal conductivity of aluminium) and magnetic conductivity (suitable for 430 stainless steel induction cooker) should be considered. Titanium pot boiling: Although titanium pot has no coating and rust-proof film, the boiling process is also essential! The newly purchased titanium pot is cleaned with detergent first, then rinsed with hot water to remove impurities such as oil and floating ash. Then pour water into the pot, add a little white vinegar, put it on the stove to boil, turn off the fire, and rinse with hot water to remove impurities such as metal and oil. The washed titanium pot is placed on the stove again. After drying and removing the water, turn off the fire. Pour a little cooking oil while the pot is warm. Spread the cooking oil evenly on the inner wall of the pot with a soft cloth. Or it is better to apply lard evenly for 1-2 hours or more. Use of titanium pot: Titanium pot has excellent thermal conductivity and energy storage. When used, medium and small fires have the effect of general pots and large fires. Medium and small fires can meet the needs of daily cooking. (Except for the effect of stir-frying). When oil is poured into the medium-hot pot, it turns into a small fire or keeps the medium-heat cooking. Cooking and energy saving save time and less oil fume. In addition, titanium is very active, with the increase of the number of times used, the oxide film on the surface will become thicker, and the more used, the better. Titanium pot maintenance: scientific use of titanium pot is very important. First heat the pan, then pour the oil, then heat the oil and add the food. It’s not so easy to stick to the pan. Uncertain that the pot is not hot enough, you can do a simple test with water: drop a small drop of water (1/8 teaspoon) into the pot, if the water touches the pot, it immediately becomes a drop of water, and slides along the surface of the pot, your pot has been preheated, you can pour oil! Titanium pot has many advantages, making it the most popular health pot. A healthy titanium pot can ensure the safety of a family for a lifetime!

Titanium pot is a pot made of 99.5% titanium metal as contact layer, pure aluminum as intermediate layer, magnetic conductive 430 stainless steel as bottom layer, three-layer composite structure, and integrated pressing. Why not use pure titanium single layer structure to make pots? That’s because both thermal conductivity (good thermal conductivity of aluminium) and magnetic conductivity (suitable for 430 stainless steel induction cooker) should be considered. Titanium pot boiling: Although titanium pot has no coating and rust-proof film, the boiling process is also essential! The newly purchased titanium pot is cleaned with detergent first, then rinsed with hot water to remove impurities such as oil and floating ash. Then pour water into the pot, add a little white vinegar, put it on the stove to boil, turn off the fire, and rinse with hot water to remove impurities such as metal and oil. The washed titanium pot is placed on the stove again. After drying and removing the water, turn off the fire. Pour a little cooking oil while the pot is warm. Spread the cooking oil evenly on the inner wall of the pot with a soft cloth. Or it is better to apply lard evenly for 1-2 hours or more. Use of titanium pot: Titanium pot has excellent thermal conductivity and energy storage. When used, medium and small fires have the effect of general pots and large fires. Medium and small fires can meet the needs of daily cooking. (Except for the effect of stir-frying). When oil is poured into the medium-hot pot, it turns into a small fire or keeps the medium-heat cooking. Cooking and energy saving save time and less oil fume. In addition, titanium is very active, with the increase of the number of times used, the oxide film on the surface will become thicker, and the more used, the better. Titanium pot maintenance: scientific use of titanium pot is very important. First heat the pan, then pour the oil, then heat the oil and add the food. It’s not so easy to stick to the pan. Uncertain that the pot is not hot enough, you can do a simple test with water: drop a small drop of water (1/8 teaspoon) into the pot, if the water touches the pot, it immediately becomes a drop of water, and slides along the surface of the pot, your pot has been preheated, you can pour oil! Titanium pot has many advantages, making it the most popular health pot. A healthy titanium pot can ensure the safety of a family for a lifetime!

Titanium alloy is an ideal armor material only in terms of performance. We know that armored steel is mainly used as armor in armored vehicles, while some light vehicles, such as infantry chariots, paratroopers and armored conveyors, use aluminum alloy armor to reduce weight. However, the hardness and specific strength of aluminium alloy armor are much lower than that of steel, and it can not withstand high temperature. When hit by armor-piercing projectiles, it will produce toxic gases locally. But after all, aluminium alloy is very light. When it is used as armor, under the premise of the same protective force for armor-piercing projectiles, the thickness of aluminium alloy is much higher than that of steel, but the weight can be lighter. But titanium alloys also have a fatal defect, which is expensive. This is expensive, on the one hand, the high-performance titanium alloy material itself is very expensive; on the other hand, more importantly, it is difficult to process titanium alloys, especially titanium alloy welding, which is very difficult. Generally speaking, the price of titanium alloy armor with the same protective force is 10-20 times higher than that of steel. So for a long time, the use of titanium alloy armor is generally in the aircraft and individual body armor. The Soviet Union used titanium alloy to make pressure hulls of submarines. As a result, the “Serra” class nuclear submarine is called “goldfish”, and its cost per ton exceeds the price of gold of the same weight. Only three countries in the world, China, the United States and Russia, have carried out special research on marine titanium alloys and established their own marine titanium alloys system. Moreover, titanium alloys have some defects. According to the related papers, under specific load conditions, projectiles only need a very small amount of energy to cause the destruction of titanium alloy armor, so it is not scientific to completely replace steel with titanium alloys even if it is rich. By the 1990s, some changes had taken place in titanium alloy armor. Represented by the United States, many countries began to study low-cost titanium alloys used in armored vehicles related technology. The price of titanium alloy armor has been reduced by about 40% through the use of new technology and new technology, such as electron beam welding, which finally makes it possible to use titanium alloy materials. The U.S. plan to upgrade M1A2 tanks in the 1990s is to use titanium alloy to make hatch covers, top armor decks, etc. instead of its original steel components, M1 tanks using titanium alloy components can reduce the weight by nearly 500 kg, while the protective force remains unchanged. U.S. military research also points out that the same technology can be used in M2 “Bradley” and M13 armored conveyors, which, of course, needs to be further reduced in the cost of titanium alloy manufacturing. In addition, in the development of EFV Marine Expeditionary Vehicle, the U.S. military also considered using titanium alloy armor, or using titanium alloy to manufacture the vehicle’s mobile system components, to reduce weight. China’s new combat vehicles use titanium alloys to make the body structure, which is obviously better in weight and protection than the previous use of aluminum alloy or steel. So what is this kind of chariot? First of all, it is still in the key technological stage, so it will not be the vehicle that has begun to equip the army. Thus, the 15-type lightweight main battle tank, 05-type amphibious assault vehicle, amphibious infantry chariot family and 04A infantry chariot can be excluded. Weapons and Equipment Group has rich experience in using titanium alloy materials in army weapons. A large number of large titanium alloy parts including titanium alloy shelves are used in the AH-4 type 155 mm ultra-light howitzer. This fact can also illustrate from the side that the Armament Group has a deep foundation in casting, welding and machining of large titanium alloy parts. At the Zhuhai Air Show in 2012, a staff member of the factory interviewed us next to the AH-4 ultra-light artillery with a mysterious smile and said, “After mastering this technology, we will have one hundred links, and there will be more new equipment using titanium alloy in the future, you wait and see.” According to the information disclosed by relevant news, the structure frame material and some armor of new type armored vehicles in China are made of titanium alloy material. This first shows that this is an armored vehicle which has decided to use titanium alloy to make a large number of basic structures from the beginning of design, which is the world’s first.

Titanium alloy is an ideal armor material only in terms of performance. We know that armored steel is mainly used as armor in armored vehicles, while some light vehicles, such as infantry chariots, paratroopers and armored conveyors, use aluminum alloy armor to reduce weight. However, the hardness and specific strength of aluminium alloy armor are much lower than that of steel, and it can not withstand high temperature. When hit by armor-piercing projectiles, it will produce toxic gases locally. But after all, aluminium alloy is very light. When it is used as armor, under the premise of the same protective force for armor-piercing projectiles, the thickness of aluminium alloy is much higher than that of steel, but the weight can be lighter. But titanium alloys also have a fatal defect, which is expensive. This is expensive, on the one hand, the high-performance titanium alloy material itself is very expensive; on the other hand, more importantly, it is difficult to process titanium alloys, especially titanium alloy welding, which is very difficult. Generally speaking, the price of titanium alloy armor with the same protective force is 10-20 times higher than that of steel. So for a long time, the use of titanium alloy armor is generally in the aircraft and individual body armor. The Soviet Union used titanium alloy to make pressure hulls of submarines. As a result, the “Serra” class nuclear submarine is called “goldfish”, and its cost per ton exceeds the price of gold of the same weight. Only three countries in the world, China, the United States and Russia, have carried out special research on marine titanium alloys and established their own marine titanium alloys system. Moreover, titanium alloys have some defects. According to the related papers, under specific load conditions, projectiles only need a very small amount of energy to cause the destruction of titanium alloy armor, so it is not scientific to completely replace steel with titanium alloys even if it is rich. By the 1990s, some changes had taken place in titanium alloy armor. Represented by the United States, many countries began to study low-cost titanium alloys used in armored vehicles related technology. The price of titanium alloy armor has been reduced by about 40% through the use of new technology and new technology, such as electron beam welding, which finally makes it possible to use titanium alloy materials. The U.S. plan to upgrade M1A2 tanks in the 1990s is to use titanium alloy to make hatch covers, top armor decks, etc. instead of its original steel components, M1 tanks using titanium alloy components can reduce the weight by nearly 500 kg, while the protective force remains unchanged. U.S. military research also points out that the same technology can be used in M2 “Bradley” and M13 armored conveyors, which, of course, needs to be further reduced in the cost of titanium alloy manufacturing. In addition, in the development of EFV Marine Expeditionary Vehicle, the U.S. military also considered using titanium alloy armor, or using titanium alloy to manufacture the vehicle’s mobile system components, to reduce weight. China’s new combat vehicles use titanium alloys to make the body structure, which is obviously better in weight and protection than the previous use of aluminum alloy or steel. So what is this kind of chariot? First of all, it is still in the key technological stage, so it will not be the vehicle that has begun to equip the army. Thus, the 15-type lightweight main battle tank, 05-type amphibious assault vehicle, amphibious infantry chariot family and 04A infantry chariot can be excluded. Weapons and Equipment Group has rich experience in using titanium alloy materials in army weapons. A large number of large titanium alloy parts including titanium alloy shelves are used in the AH-4 type 155 mm ultra-light howitzer. This fact can also illustrate from the side that the Armament Group has a deep foundation in casting, welding and machining of large titanium alloy parts. At the Zhuhai Air Show in 2012, a staff member of the factory interviewed us next to the AH-4 ultra-light artillery with a mysterious smile and said, “After mastering this technology, we will have one hundred links, and there will be more new equipment using titanium alloy in the future, you wait and see.” According to the information disclosed by relevant news, the structure frame material and some armor of new type armored vehicles in China are made of titanium alloy material. This first shows that this is an armored vehicle which has decided to use titanium alloy to make a large number of basic structures from the beginning of design, which is the world’s first.

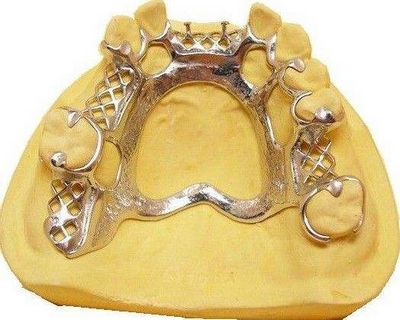

(1) Orthodontics. Orthodontics refers to the science of correcting tooth dislocation by mechanical or functional instruments. In order to correct tooth dislocation, external force must be applied through different instruments. The detachable device consists of separate acrylic acid (PMMA) sheets, which are fixed to the patient’s teeth by filamentary elements. The acrylic sheet is separated and applied to the teeth by expanding screw (rotating shaft with left and right threads). In fixing technology, the fixed object (bracket and oral tube) is used to exert force on the teeth through the filamentous original part. Now, except stainless steel, pure titanium is used for fixing and fixing components because of its light weight and high corrosion resistance. For dental arch wires and spring elements, titanium alloy is particularly noticeable because of its lower modulus of elasticity than stainless steel and higher strength than pure titanium. The tensile strength of Beta-type titanium alloy can reach 1300 MPa after cold deformation. The processability of Beta-type alloy is better, and it can even be produced into fine filamentary components. The mechanical properties of cold-worked grade 4 pure titanium are similar to that of beta alloy, so it can replace beta alloy. In addition, Ti-Ni alloy wire shape memory alloy wire has been applied because of its pseudoelasticity, which is based on stress-induced martensitic transformation. (2) Repair. Dental prosthetics refers to the replacement of defective teeth or other parts with prostheses to reproduce the masticatory, aesthetic and pronunciation functions of teeth. As a new material in dental laboratory, the problem of titanium early processing has been solved, and the application of titanium in dental restoration has become more and more successful. Titanium is used not only as ordinary castings, but also as crowns and bridges with ceramics and teeth. Dental precision casting is often used to process titanium parts. For the large structure of fixed implants, the electrochemical properties of cast titanium are comparable to those of industrialized intraosseous implants, which reduces the electrochemical properties and the harm of electrochemical and corrosion effects. In addition, compared with gold-based alloys, titanium has the advantages of economy. Therefore, it is considered to be an ideal material for composite, permanent and removable restorations. Compared with other alloys with cladding ceramics, the thermal expansion coefficient of titanium is very low, so suitable ceramics need to be embedded. The oxidation degree of titanium increases at high temperature, the grain size and microstructure coarsen, and the beta transformation occurs at 882 C. Therefore, the highest calcination temperature of cladding ceramics on titanium surface is 800 C. (3) Dental implantation. Dental implantation refers to the implantation of artificial pillars into the periosteum or bone to reconstruct the masticatory function, aesthetic characteristics and pronunciation function. In modern dental surgery, intraosseous implants are recognized as a method to replace teeth, create permanent dental pillars and stabilize removable dentures. Titanium and titanium alloy dental implants have been used for more than 40 years and are manufactured according to the corresponding standards. A1203 shot peening or titanium plasma flame treatment is usually used to coarsen the surface of implants to promote the adhesion between implants and bone. Local use of absorbable alkyl apatite in the surface area (cortex) will also promote the attachment of key parts of the implant to the bone.

(1) Orthodontics. Orthodontics refers to the science of correcting tooth dislocation by mechanical or functional instruments. In order to correct tooth dislocation, external force must be applied through different instruments. The detachable device consists of separate acrylic acid (PMMA) sheets, which are fixed to the patient’s teeth by filamentary elements. The acrylic sheet is separated and applied to the teeth by expanding screw (rotating shaft with left and right threads). In fixing technology, the fixed object (bracket and oral tube) is used to exert force on the teeth through the filamentous original part. Now, except stainless steel, pure titanium is used for fixing and fixing components because of its light weight and high corrosion resistance. For dental arch wires and spring elements, titanium alloy is particularly noticeable because of its lower modulus of elasticity than stainless steel and higher strength than pure titanium. The tensile strength of Beta-type titanium alloy can reach 1300 MPa after cold deformation. The processability of Beta-type alloy is better, and it can even be produced into fine filamentary components. The mechanical properties of cold-worked grade 4 pure titanium are similar to that of beta alloy, so it can replace beta alloy. In addition, Ti-Ni alloy wire shape memory alloy wire has been applied because of its pseudoelasticity, which is based on stress-induced martensitic transformation. (2) Repair. Dental prosthetics refers to the replacement of defective teeth or other parts with prostheses to reproduce the masticatory, aesthetic and pronunciation functions of teeth. As a new material in dental laboratory, the problem of titanium early processing has been solved, and the application of titanium in dental restoration has become more and more successful. Titanium is used not only as ordinary castings, but also as crowns and bridges with ceramics and teeth. Dental precision casting is often used to process titanium parts. For the large structure of fixed implants, the electrochemical properties of cast titanium are comparable to those of industrialized intraosseous implants, which reduces the electrochemical properties and the harm of electrochemical and corrosion effects. In addition, compared with gold-based alloys, titanium has the advantages of economy. Therefore, it is considered to be an ideal material for composite, permanent and removable restorations. Compared with other alloys with cladding ceramics, the thermal expansion coefficient of titanium is very low, so suitable ceramics need to be embedded. The oxidation degree of titanium increases at high temperature, the grain size and microstructure coarsen, and the beta transformation occurs at 882 C. Therefore, the highest calcination temperature of cladding ceramics on titanium surface is 800 C. (3) Dental implantation. Dental implantation refers to the implantation of artificial pillars into the periosteum or bone to reconstruct the masticatory function, aesthetic characteristics and pronunciation function. In modern dental surgery, intraosseous implants are recognized as a method to replace teeth, create permanent dental pillars and stabilize removable dentures. Titanium and titanium alloy dental implants have been used for more than 40 years and are manufactured according to the corresponding standards. A1203 shot peening or titanium plasma flame treatment is usually used to coarsen the surface of implants to promote the adhesion between implants and bone. Local use of absorbable alkyl apatite in the surface area (cortex) will also promote the attachment of key parts of the implant to the bone.