Author Archives: mywp

What is Titanium Damascus?

What is Titanium Damascus?

First of all, titanium Damascus is an innovative material, also referred to as moku-ti or Ti Moku

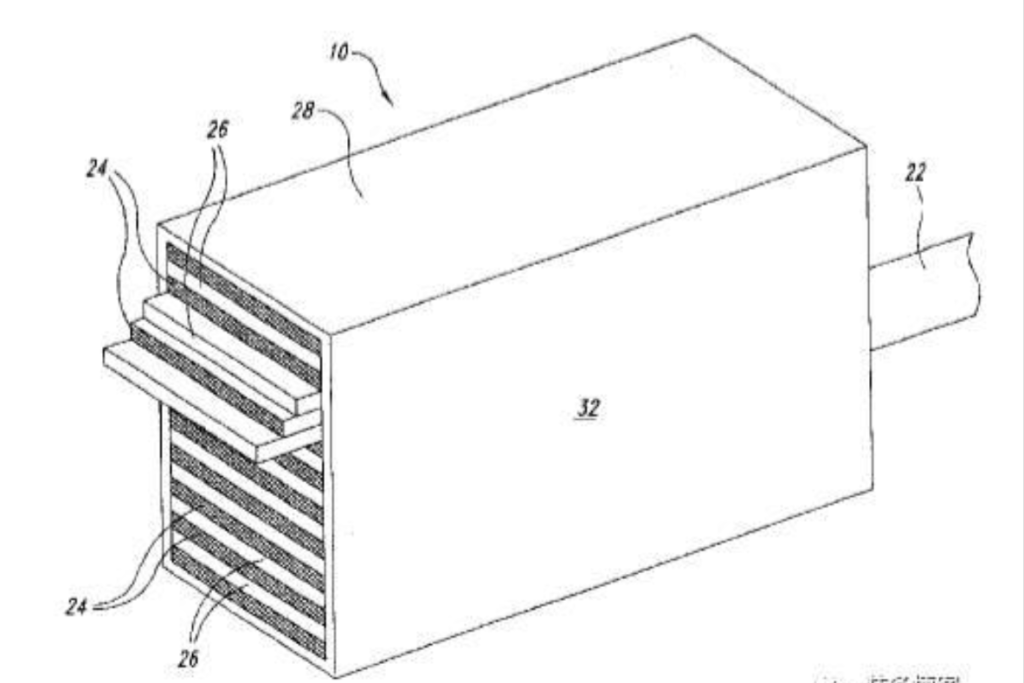

Technical specifications Titanium Damascus is similar to Damascus steel. Damascus steel is forged from two or more kinds of steel. Titanium Damascus is composed of two or more kinds of titanium alloy (CP and 6al4v at present). Timascus has the characteristics of corrosion resistance, non magnetism and light texture. It has the beautiful pattern and appearance of Damascus steel, and has no disadvantages of steel. Different titanium alloys are placed in a metal box, filled with inert gas, heated and pressed to forge the two alloys into layers. (patent illustration submitted)

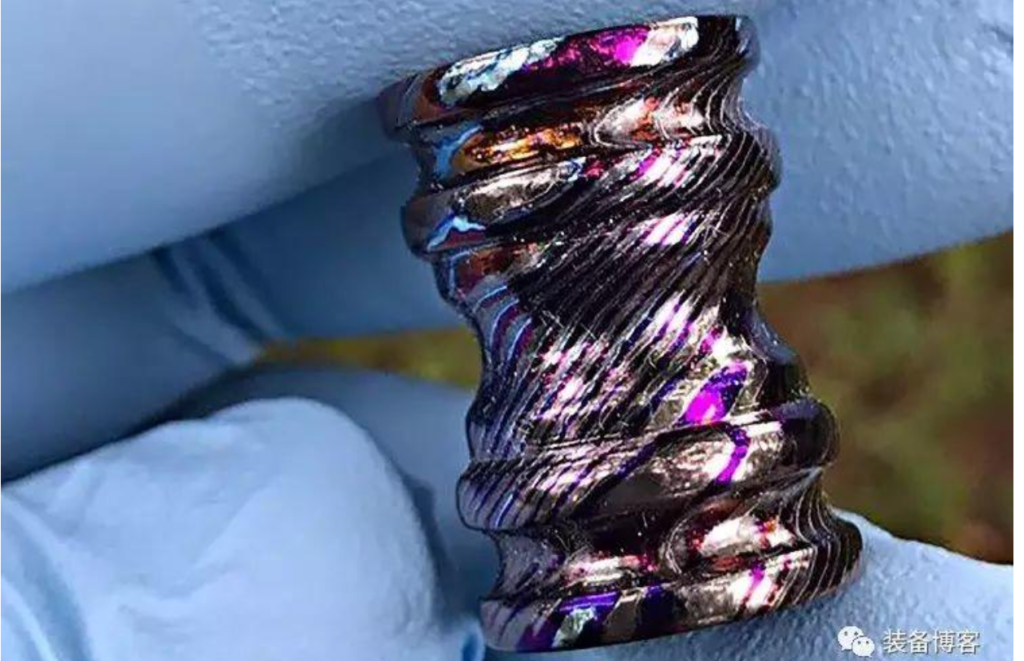

Technical specifications Titanium Damascus is similar to Damascus steel. Damascus steel is forged from two or more kinds of steel. Titanium Damascus is composed of two or more kinds of titanium alloy (CP and 6al4v at present). Timascus has the characteristics of corrosion resistance, non magnetism and light texture. It has the beautiful pattern and appearance of Damascus steel, and has no disadvantages of steel. Different titanium alloys are placed in a metal box, filled with inert gas, heated and pressed to forge the two alloys into layers. (patent illustration submitted)  At present, the coloring process of timascus leather usually uses heating to achieve color change instead of anodizing. Of course, all the current safe coloring technologies can be applied to timascus. In the future, different alloy combination steels will have different colors. (because titanium has no carbide, this kind of steel is mostly used for cutting tools and furniture decoration.)

At present, the coloring process of timascus leather usually uses heating to achieve color change instead of anodizing. Of course, all the current safe coloring technologies can be applied to timascus. In the future, different alloy combination steels will have different colors. (because titanium has no carbide, this kind of steel is mostly used for cutting tools and furniture decoration.)

Except for milling, the manufacturing process of timascus is basically the same as that of any other titanium alloy. The mixed type titanium has different hardness. In cutting, different hardness will lead to cutter wear, but the use of fillet cutting machine, more conducive to processing.

Except for milling, the manufacturing process of timascus is basically the same as that of any other titanium alloy. The mixed type titanium has different hardness. In cutting, different hardness will lead to cutter wear, but the use of fillet cutting machine, more conducive to processing.

Anodized Colors of Titanium

Anodized Colors of Titanium

Below photo is the available colors of titanium Grade 5. You can see there are Green,Purple,Pink,blue,Gold,Bronze, Blue Purple,Blue Green colors. Just take this photo as a referance.

Semi-finished Titanium Bolts after Forging

Semi-finished Titanium Bolts after Forging

In the video,there are Tens of thousands of seminfinished titanium bolts.The finish looks like grey white color,they are all generated after Acid and alkali washed after forging. It is a processing for titanium bolts production.For the normal Torx socket,they are usually forged out by mold when doing head forging.After forging the head blank is formed and then CNC turning the head types. The head forging can save material cost and increase head strength of the titanium bolts. For titanium Grade 5,usually they are heat forged but not cold forged.When doing cold forging,it will generate cracks.But when do heat forging,the finish of titanium will generate a thick oxide layer.So we have to remove it by Acid and alkali.Titanium Fasteners Manufacturer

Titanium Fasteners Manufacturer

HOSN Titanium is a manufacturer of titanium fasteners.We produce both standard titanium fasteners and customized ones. Every link of processing including raw material will be high specific controled just to ensure high quality. Most of our titanium fasteners heads will be forged just to ensure high strength. Rolling threads will ensure strength of threads. Other processing including CNC turning,milling will ensure high precision of dimensions. Available colors including Oilslick,Black,Rainbow,Blue,Purple,Green,Gold,Bronze and Red colors ensuring beautiful finish of titanium fasteners.Customization services

Photos of Titanium Springs

Beautiful Titanium Springs

This is a video about titanium springs which are used for bicycles and motorcycles rearshocks.All titanium springs are made from titanium alloy which has low weight, excellenet elasticity, long lifetime and rustless features. All titanium springs can be colored to Oilslick,Black,Rainbow,Blue,Gold,Purple,Green,Bronze and Red colors.Customized Titanium Parts on CNC Milling

Customized Titanium Parts on CNC Milling

This is a video of Titanium parts in CNC milling from Machining Center.All sizes will be high precision controled.All of these parts are customized titanium parts from customers.

Oilslick Titanium Springs for Mountain Bikes

Oilslick Titanium Spring for Mountain Biks. Now Oilslick titanium springs is popular and most persons like it.So just check this video,I think it is really looks beautiful.

Titanium Bolts Head Forming / Forging

This video is about titanium bolts head forming / forging.

Now most titanium bolts heads including the botton head,cap head,hex flange head and the 12 point flange head are forged to a roughcast at first.It has many advantages.- Saving material cost and machining cost. Usually the bolts head diameter is much bigger than the thread and shaft diameter,if totally turn it from titanium blanks,its material cost and machining time will be much longer.So use smaller diameter titanium rods to punch the head to a roughcast and then CNC turn it.We can think we will reduce material cost and machining time.

- The titanium bolt forging can increase Head Strength.

- Resolve problem of some head sizes can’t be make out by cold punching.Especially for the torx socket titanium bolts,they can’t be cold punched out.So the head forging can forge the torx socket out at the same time. Also the same as the 12 point titanium bolts and nuts,they are all head forged out at the same time.

- The Grade 5 titanium bolts have to be forged out by heating.If not,the head will generate cracks.So if heating,the part will be oxided and there will be an ugly tough oxide layer on the finish.to remove it,we have to remove it by acid washing.

- The finish of the torx socket or the 12 point bolts or nuts will be not bright like the normal hex socket or hex flange ones.But they are will be still beautiful.