Several Surface Treatment Methods of Titanium Bolt

The appearance of titanium bolt is like steel, with silver white luster. It is a transition metal. Titanium bolt has high strength, small density, high hardness, high melting point and strong corrosion resistance. Due to its stable chemical properties, it has good high temperature resistance, low temperature resistance, strong acid resistance, strong alkali resistance, high strength and low density.

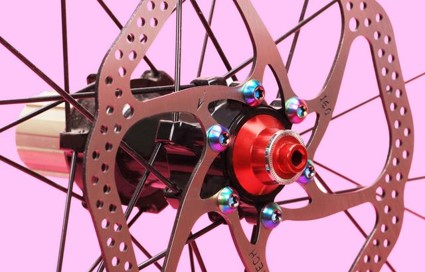

The color of titanium bolt is silver gray without any surface treatment, as shown in the following photo,

Sometimes, we find many colorful titanium bolts on top grade bicycles or cars. The surface of these bolts is so bright and colorful after some surface treatment. Today, we will briefly introduce the surface treatment of titanium bolts

Removal of reaction layer on the surface of titanium bolt

Due to the low density of titanium bolt, the inertia of titanium liquid flow is small, and the flow performance is poor. In the process of production, it is easy to cause defects such as pores on the surface and inside of titanium bolt. In order to make the titanium bolt bright and colorful, it is necessary to remove the reaction layer on the surface of the titanium bolt. There are two ways to remove the reaction layer on the surface of titanium bolt

1) Sand blasting: sand grains are blasted on the surface of titanium bolts by sand blasting, resulting in intense sparks. When the temperature rises, the surface of titanium bolts will react, forming secondary pollution and affecting the surface quality. The time is 15-30 seconds, only removing the sand sticking, surface sintering layer and part of oxide layer on the casting surface. The rest of the surface reaction layer structure should be removed quickly by chemical pickling.

2) Acid pickling: the surface reaction layer of titanium bolt can be removed quickly and effectively by the method of cleaning and acid pickling, and other metal elements will not be polluted.

Treatment of casting defects of titanium bolts

In the production process of titanium bolts, there may be internal porosity and shrinkage internal defects: at this time, it can be removed by hot isostatic pressing technology.

Grinding and polishing

1) Titanium bolts have high chemical reactivity, low thermal conductivity, high viscosity, low mechanical grinding ratio, and are easy to react with abrasive Abrasives. Ordinary abrasives are not suitable for the grinding and polishing of titanium screws. It is better to use super hard abrasives with good thermal conductivity, such as diamond, CBN, etc,

2) Chemical polishing: chemical polishing is to achieve the purpose of leveling and polishing through the oxidation-reduction reaction of metal in the chemical medium. It has the advantages that chemical polishing has nothing to do with the hardness of metal, polishing area and structure shape. All parts contacting with polishing fluid are polished without special and complex equipment. It is easy to operate and is more suitable for polishing of precision titanium screws with complex structure. However, chemical polishing is difficult to control in process parameters. It is required to have good polishing effect on titanium bolts without affecting the precision of titanium bolts.

Coloring

In order to increase the aesthetic feeling of titanium bolt, make the surface of titanium bolt more colorful and bright, and prevent the continuous oxidation of titanium bolt under natural conditions. General bolt manufacturers will adopt surface nitriding treatment, atmospheric oxidation and anodizing surface coloring treatment to form a light yellow or golden yellow surface and improve the aesthetic feeling of titanium bolts. The anodizing method uses the interference of titanium oxide film on the light to produce natural color, which can form colorful color on the titanium surface by changing the cell voltage.

Of course, titanium bolt customization is mainly based on the different needs of users for different surface treatment methods. The practical application environment of titanium bolt is the main reason for the surface treatment of titanium bolt, which is just the conventional treatment of titanium screw fastener.

This Article from Baoji HOSN Titanium Co., Ltd.