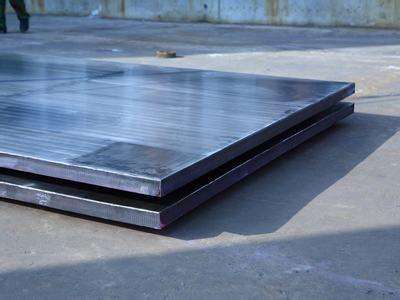

Metal laminated composite sheet can achieve perfect metallurgical combination of different metals with very wide differences in strength, melting point and thermal expansion coefficient. It integrates the advantages of different materials and gives full play to the use characteristics of different materials. It greatly saves precious metal materials, reduces the manufacturing cost of equipment and makes precious metals in good condition. Multidisciplinary applications are possible. Composites produced by explosive composite technology can achieve perfect combination of different metals without changing the composition and physical properties of the original materials. Metal composite sheets can be designed independently, and different materials can be designed and manufactured according to the need for optimal use. The metal clad sheet material not only has good weldability, formability, thermal conductivity and mechanical properties of carbon steel, but also has excellent corrosion resistance of various cladding layers. So it is widely used in petroleum, chemical industry, metallurgy, light industry, salt chemical industry, power station auxiliary machinery, desalination shipbuilding, power and marine engineering industries.

A remarkable characteristic of titanium is its strong corrosion resistance, which is due to its strong affinity to oxygen, which can generate a dense oxide film on its surface, which can protect titanium from medium corrosion. Titanium metal can form passive oxide film on the surface in most aqueous solutions. Therefore, titanium has good stability in acidic, alkaline, neutral saline solution and oxidizing medium. It has better corrosion resistance than existing stainless steel and other commonly used non-ferrous metals, and even can be compared with platinum. Therefore, titanium is widely used in various chemical reaction vessels, heat exchanger materials and anti-corrosion fields, but the disadvantage is the high cost. Especially when used as structural parts, this problem is particularly prominent. The titanium steel composite plate produced by explosive composite method has not only the corrosion resistance of titanium, but also the strength and plasticity of common steel plate as structural parts. Especially, the cost has been greatly reduced.

With the continuous progress of equipment manufacturing technology and the development of chemical industry in China, the application field of Ti-steel composite will continue to expand, and the cost of Ti-steel composite plate is slightly lower than the price of Ti-steel plate. For small and medium-sized chemical enterprises still using plastic materials or other materials as substitutes, compared with the use of Ti-steel composite plate. Life-to-price ratio, their choice of titanium steel composite plate will increase the possibility of this part of the market demand, for upstream titanium steel composite manufacturers, is also a great encouragemen