At present, medical titanium alloys have been widely used in orthodontics, prosthodontics and dental implants. Table 1 shows the dental uses of titanium and titanium alloys studied in Japan.

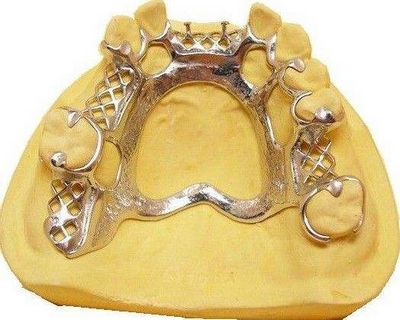

(1) Orthodontics. Orthodontics refers to the science of correcting tooth dislocation by mechanical or functional instruments. In order to correct tooth dislocation, external force must be applied through different instruments. The detachable device consists of separate acrylic acid (PMMA) sheets, which are fixed to the patient’s teeth by filamentary elements. The acrylic sheet is separated and applied to the teeth by expanding screw (rotating shaft with left and right threads). In fixing technology, the fixed object (bracket and oral tube) is used to exert force on the teeth through the filamentous original part. Now, except stainless steel, pure titanium is used for fixing and fixing components because of its light weight and high corrosion resistance. For dental arch wires and spring elements, titanium alloy is particularly noticeable because of its lower modulus of elasticity than stainless steel and higher strength than pure titanium. The tensile strength of Beta-type titanium alloy can reach 1300 MPa after cold deformation. The processability of Beta-type alloy is better, and it can even be produced into fine filamentary components. The mechanical properties of cold-worked grade 4 pure titanium are similar to that of beta alloy, so it can replace beta alloy. In addition, Ti-Ni alloy wire shape memory alloy wire has been applied because of its pseudoelasticity, which is based on stress-induced martensitic transformation. (2) Repair. Dental prosthetics refers to the replacement of defective teeth or other parts with prostheses to reproduce the masticatory, aesthetic and pronunciation functions of teeth. As a new material in dental laboratory, the problem of titanium early processing has been solved, and the application of titanium in dental restoration has become more and more successful. Titanium is used not only as ordinary castings, but also as crowns and bridges with ceramics and teeth. Dental precision casting is often used to process titanium parts. For the large structure of fixed implants, the electrochemical properties of cast titanium are comparable to those of industrialized intraosseous implants, which reduces the electrochemical properties and the harm of electrochemical and corrosion effects. In addition, compared with gold-based alloys, titanium has the advantages of economy. Therefore, it is considered to be an ideal material for composite, permanent and removable restorations. Compared with other alloys with cladding ceramics, the thermal expansion coefficient of titanium is very low, so suitable ceramics need to be embedded. The oxidation degree of titanium increases at high temperature, the grain size and microstructure coarsen, and the beta transformation occurs at 882 C. Therefore, the highest calcination temperature of cladding ceramics on titanium surface is 800 C. (3) Dental implantation. Dental implantation refers to the implantation of artificial pillars into the periosteum or bone to reconstruct the masticatory function, aesthetic characteristics and pronunciation function. In modern dental surgery, intraosseous implants are recognized as a method to replace teeth, create permanent dental pillars and stabilize removable dentures. Titanium and titanium alloy dental implants have been used for more than 40 years and are manufactured according to the corresponding standards. A1203 shot peening or titanium plasma flame treatment is usually used to coarsen the surface of implants to promote the adhesion between implants and bone. Local use of absorbable alkyl apatite in the surface area (cortex) will also promote the attachment of key parts of the implant to the bone.

(1) Orthodontics. Orthodontics refers to the science of correcting tooth dislocation by mechanical or functional instruments. In order to correct tooth dislocation, external force must be applied through different instruments. The detachable device consists of separate acrylic acid (PMMA) sheets, which are fixed to the patient’s teeth by filamentary elements. The acrylic sheet is separated and applied to the teeth by expanding screw (rotating shaft with left and right threads). In fixing technology, the fixed object (bracket and oral tube) is used to exert force on the teeth through the filamentous original part. Now, except stainless steel, pure titanium is used for fixing and fixing components because of its light weight and high corrosion resistance. For dental arch wires and spring elements, titanium alloy is particularly noticeable because of its lower modulus of elasticity than stainless steel and higher strength than pure titanium. The tensile strength of Beta-type titanium alloy can reach 1300 MPa after cold deformation. The processability of Beta-type alloy is better, and it can even be produced into fine filamentary components. The mechanical properties of cold-worked grade 4 pure titanium are similar to that of beta alloy, so it can replace beta alloy. In addition, Ti-Ni alloy wire shape memory alloy wire has been applied because of its pseudoelasticity, which is based on stress-induced martensitic transformation. (2) Repair. Dental prosthetics refers to the replacement of defective teeth or other parts with prostheses to reproduce the masticatory, aesthetic and pronunciation functions of teeth. As a new material in dental laboratory, the problem of titanium early processing has been solved, and the application of titanium in dental restoration has become more and more successful. Titanium is used not only as ordinary castings, but also as crowns and bridges with ceramics and teeth. Dental precision casting is often used to process titanium parts. For the large structure of fixed implants, the electrochemical properties of cast titanium are comparable to those of industrialized intraosseous implants, which reduces the electrochemical properties and the harm of electrochemical and corrosion effects. In addition, compared with gold-based alloys, titanium has the advantages of economy. Therefore, it is considered to be an ideal material for composite, permanent and removable restorations. Compared with other alloys with cladding ceramics, the thermal expansion coefficient of titanium is very low, so suitable ceramics need to be embedded. The oxidation degree of titanium increases at high temperature, the grain size and microstructure coarsen, and the beta transformation occurs at 882 C. Therefore, the highest calcination temperature of cladding ceramics on titanium surface is 800 C. (3) Dental implantation. Dental implantation refers to the implantation of artificial pillars into the periosteum or bone to reconstruct the masticatory function, aesthetic characteristics and pronunciation function. In modern dental surgery, intraosseous implants are recognized as a method to replace teeth, create permanent dental pillars and stabilize removable dentures. Titanium and titanium alloy dental implants have been used for more than 40 years and are manufactured according to the corresponding standards. A1203 shot peening or titanium plasma flame treatment is usually used to coarsen the surface of implants to promote the adhesion between implants and bone. Local use of absorbable alkyl apatite in the surface area (cortex) will also promote the attachment of key parts of the implant to the bone.